QHSE

Quality in every step. We don’t compromise on the health, safety or security of people. We are committed to protecting the environment where we live and work.

Quality, health, safety and environment (QHSE) standards are fundamental to all that we do. Every individual at EMGS is trained to understand the importance of QHSE and to take personal ownership of it. The health and safety of our employees, the people we work with and the communities in which we operate in are essential to us.

This is demonstrated through our experience of safely executing closer to 1000 EM surveys around the world, working with some of the largest energy companies in the world – majors, NOCs, IOCs. EMGS has passed numerous stringent QHSE related audits and Environmental Impact Assessments (EIAs) from our clients and governmental regulators around the world.

Our health and safety culture is particularly apparent in our offshore operations. The foundation of our offshore QHSE culture is built upon the following measures:

Toolbox meetings, in which everyone is given a health and safety briefing, precede each operation.

Hazard management is a strong focus, and we employ toolbox meetings, observation cards, risk assessments, management of change and one-step-back practices. Everyone working on board an EMGS vessel has the obligation to stop unsafe acts.

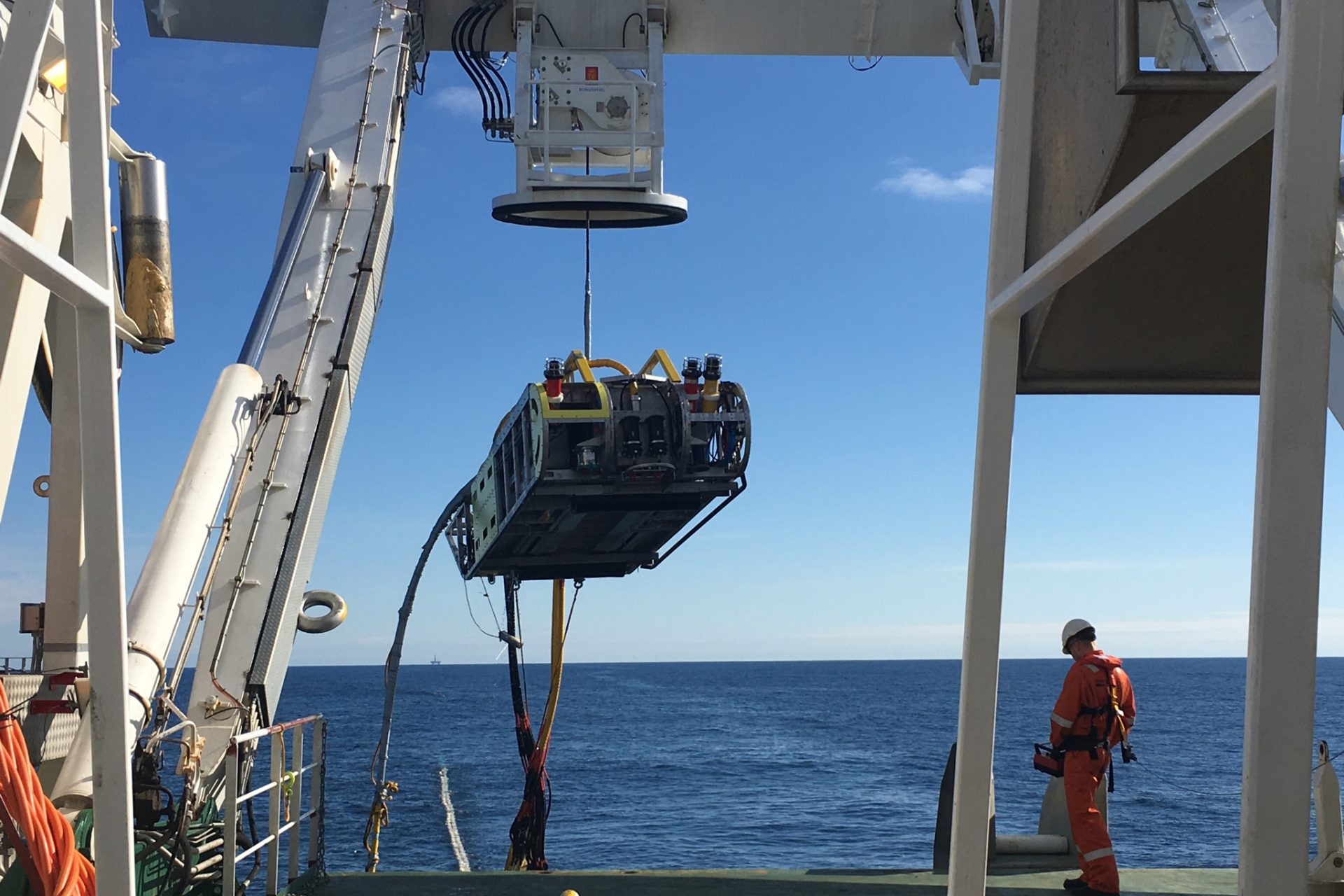

Automated equipment handling lines on our purpose-built vessels reduce manual handling. The receivers are deployed and recovered by specialist crane drivers.

Continuous weather assessment before and during operations. We can operate safely in 4–5 m swells, and our rapid receiver recovery time reduces the weather window required. Our vessels have specific permitted operations that detail what types of operation are allowed under different weather conditions.

Strict procedures govern our operations. Only designated personnel are allowed in each working area. Trained and permitted personnel only, operate high-voltage equipment. An alarmed tag-out and lockout system restricts access for unqualified personnel.

Our personnel are trained in manual handling, and we continually assess handling-tool design.